Gasification Technology

The modelling/balances research group supports laboratory and pilot gasifiers (REGA, HP-EFG) by design and standardized evaluation of the experiments. Our numerical and flowsheet simulation models are built and further developed on the basis of the experimental data obtained in this way.

The modelling/balances research group supports laboratory and pilot gasifiers (REGA, HP-EFG) by design and standardized evaluation of the experiments. Our numerical and flowsheet simulation models are built and further developed on the basis of the experimental data obtained in this way.

Special balancing methods enable the determination of (i) reactor data that cannot be measured directly, (ii) characteristic key parameters for process evaluation and scale-up and (iii) validation data for the simulation from the experiments.

The flowsheet models (ASPEN plus) are used for design of experiments (determination of fuel-specific operating parameters), for validation of the experimental results and for scale-up calculations. The data and key parameters determined from the operation of the pilot gasifier thus allow well-founded scale-up calculations to transfer the fuel-specific results to the technical scale.

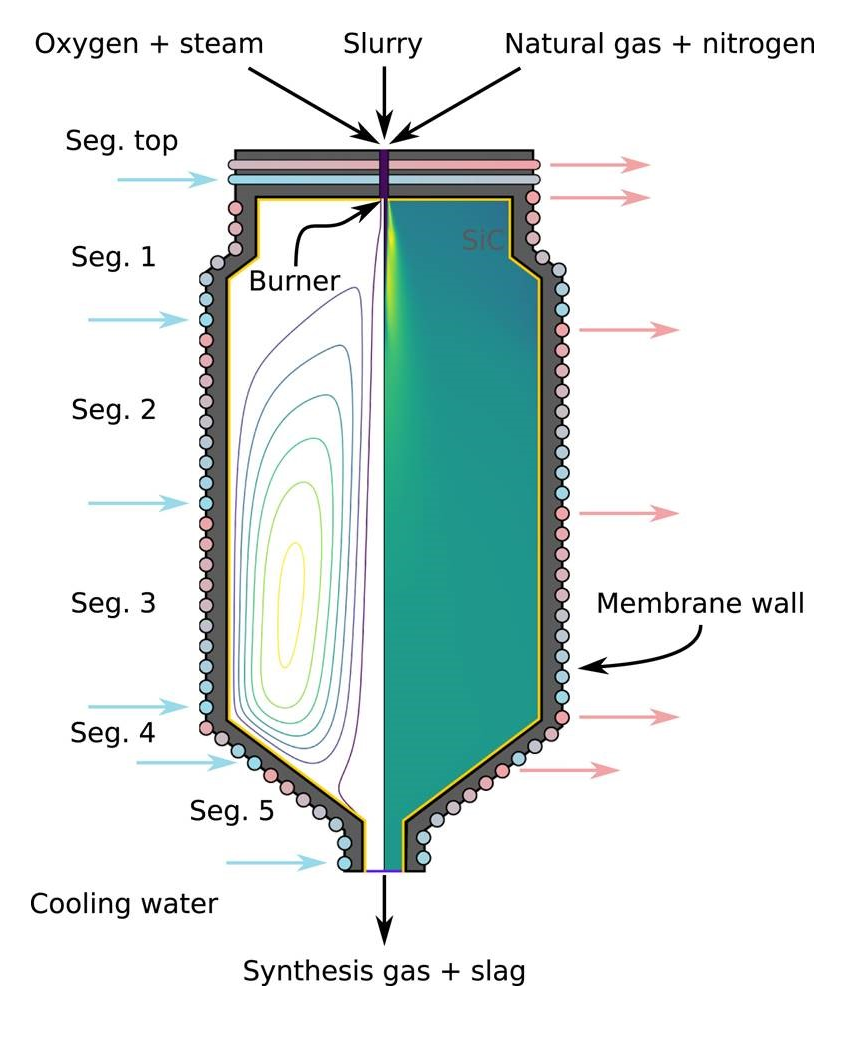

Since both fuel conversion and process efficiency are strongly determined by local mixing and flow conditions in the gasifier, a suitable numerical model is essential for the design of an industrial-scale gasifier. Therefore, various submodels for evaporation, solid kinetics, gas phase kinetics, heat transfer and slag behavior were developed and integrated into CFD models for the existing gasifiers.

Research interests

- Balancing of gasification processes (e.g. REGA, HP-EFG im CCLab)

- Validation of process quality with characteristic key parameters

- Detailed modeling of combustion and gasification processes using CHEMKIN, Aspen Plus® und Fluent

- Numerical simulation of entrained flow gasifiers using RANS

- Evaluation of mathematical models and simulation tools

- Flowsheet simulation (Aspen Plus®) for gasification experiments (REGA, HP-EFG im CCLab)

Team

Completed PhD

- M.Dammann

Numerical modelling and simulation of atmospheric entrained flow gasification of surrogate fuels

Dissertation, KIT, 2024