Analysis of gaseous pyrolysis products

In addition to solids and condensable products, various gaseous species are released during the pyrolysis process. In order to balance the overall process, it is essential to fully detect and analyze the gases produced. The composition of the pyrolysis gases can furthermore provide important information on the decomposition mechanisms occurring during pyrolysis.

The pyrolysis group develops and operates extensive online and offline analytical equipment for the investigation of pyrolysis gases:

![]()

Micro Gaschromatograph Inficon µGC Fusion

- Separation and detection of gas components using thermal conductivity detector and flame ionization detector.

- Quantification of N2, H2, O2, CO, CO2 and CH4 as well as C2-C7 hydrocarbons, and BTEX

- Self-supply of samples by integrated sample gas pump from gas bag or sample gas line (pilot reactor STYX)

- Analysis time of a few minutes allows high-resolution online process monitoring

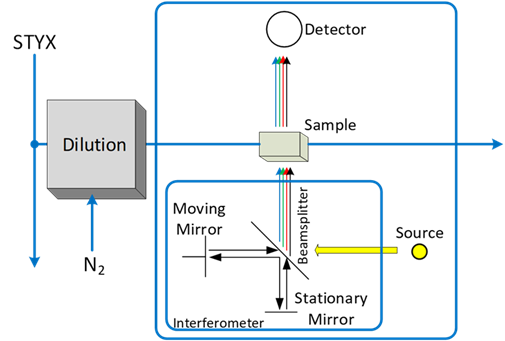

FTIR spectrometer Gasmet CX4000

- Identification of e.g. NH3, HCN, NO, NO2, SO2, HCl, HBr and heteroatom-bearing hydrocarbons

- Continuous measurement (pilot reactor STYX)

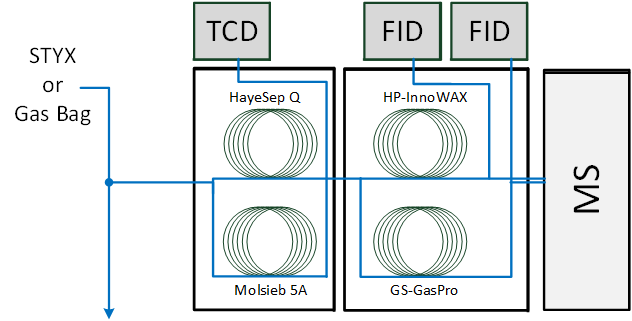

Online GC-FID/TCD-MS

- Combination of multiple separation columns and detectors enables comprehensive identification of gas components in addition to µGC and FTIR

- Quantification of N2, H2, O2, CO, CO2 and CH4 as well as C2-C7 hydrocarbons, plus BTX and selected higher HCs

- Self-supply of samples by integrated sample gas pump from gas bag or sample gas line (pilot reactor STYX)

- Analysis time 30-60 minutes possible

Pilot reactor STYX: recording of density, calorific value and volume flow of the pyrolysis gases as well as continuous O2 recording for process monitoring and balancing